High Tensile Strength 6*19s+FC Zinc Coated Steel Wire Rope 12 mm 21 mm 23 mm for Well Drilling

High Tensile Strength 6*19S+FC Zinc Coated Steel Wire Rope 12 mm 21 mm 23 mm for Well Drilling Application The galvanize

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | 6*7 7*7 6*19 7*19 |

| MOQ | 1 Ton |

| Samples | Free Samples |

| Transport Package | Coil Packing, Z2 Packing, Wooden Reel Packing |

| Specification | 6*7 7*7 6*19 7*19 |

| Trademark | Yunhe |

| Origin | China |

| HS Code | 7312100000 |

| Production Capacity | 12000 Per Month |

Product Description

High Tensile Strength 6*19S+FC Zinc Coated Steel Wire Rope 12 mm 21 mm 23 mm for Well Drilling

Application

The galvanized steel wire strand is used for overhead ground lines or electrical power transmission lines. Stay or guy wire strands are produced for use with poles, towers, or any other form of guying.

Standard

Concentrically stranded Galvanized steel wire strand available in class "A", "B" and "C" galvanizing, "A" being the least heavy and "C" being the most heavy. Manufactured without welds per ASTM A-363 or with welds per ASTM A-475. Strands are formed to remain substantially in place when severed.

Specification

ASTM A475, ASTM A363, BS183:1972

Zinc-coated grade of steel strand wire /guy wire : Class A ,Class B and class C

| Nominal Diameter | Approx. Weight | Nominal Tensile Strength of Rope (Mpa) | |||||||||

| 1570 | 1670 | 1770 | 1870 | ||||||||

| Minimum Breaking Load of Rope | |||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IER/IES |

| mm | kg/100m | KN | |||||||||

| 8 | 22.10 | 21.40 | 27.00 | 29.40 | 34.70 | 31.30 | 36.90 | 33.10 | 39.20 | 35.00 | 41.40 |

| 9 | 28.00 | 27.10 | 34.20 | 37.30 | 44.00 | 39.60 | 46.70 | 42.00 | 49.60 | 44.30 | 52.40 |

| 10 | 34.60 | 33.40 | 42.20 | 46.00 | 54.30 | 48.90 | 57.70 | 51.80 | 61.20 | 54.70 | 64.70 |

| 11 | 41.90 | 40.40 | 51.10 | 55.60 | 65.70 | 59.20 | 69.90 | 62.70 | 74.10 | 66.20 | 78.20 |

| 12 | 49.90 | 48.00 | 60.80 | 66.20 | 78.20 | 70.40 | 83.20 | 74.60 | 88.10 | 78.80 | 93.10 |

| 13 | 58.50 | 56.40 | 71.30 | 77.70 | 91.80 | 82.60 | 97.60 | 87.60 | 103.00 | 92.50 | 109.00 |

| 14 | 67.90 | 65.40 | 82.70 | 90.10 | 106.00 | 95.90 | 113.00 | 101.00 | 120.00 | 107.00 | 126.00 |

| 16 | 88.70 | 85.40 | 108.00 | 117.00 | 139.00 | 125.00 | 147.00 | 132.00 | 156.00 | 140.00 | 165.00 |

| 18 | 112.00 | 108.00 | 137.00 | 149.00 | 176.00 | 158.00 | 187.00 | 168.00 | 198.00 | 177.00 | 209.00 |

| 20 | 139.00 | 133.00 | 169.00 | 184.00 | 217.00 | 195.00 | 231.00 | 207.00 | 244.00 | 219.00 | 256.00 |

| 22 | 168.00 | 162.00 | 204.00 | 222.00 | 262.00 | 236.00 | 279.00 | 251.00 | 296.00 | 265.00 | 313.00 |

| 24 | 199.00 | 192.00 | 243.00 | 264.00 | 312.00 | 281.00 | 332.00 | 298.00 | 352.00 | 315.00 | 372.00 |

| 26 | 234.00 | 226.00 | 285.00 | 310.00 | 367.00 | 330.00 | 390.00 | 350.00 | 413.00 | 370.00 | 437.00 |

| 28 | 271.00 | 262.00 | 330.00 | 360.00 | 425.00 | 384.00 | 453.00 | 406.00 | 480.00 | 429.00 | 507.00 |

| 30 | 312.00 | 300.00 | 380.00 | 414.00 | 488.00 | 440.00 | 520.00 | 466.00 | 551.00 | 493.00 | 582.00 |

| 32 | 355.00 | 342.00 | 432.00 | 471.00 | 556.00 | 501.00 | 591.00 | 531.00 | 627.00 | 561.00 | 662.00 |

| 34 | 400.00 | 386.00 | 488.00 | 532.00 | 628.00 | 565.00 | 668.00 | 600.00 | 707.00 | 633.00 | 747.00 |

| 36 | 448.00 | 432.00 | 546.00 | 596.00 | 704.00 | 634.00 | 758.00 | 672.00 | 793.00 | 710.00 | 838.00 |

| 38 | 500.00 | 482.00 | 609.00 | 664.00 | 784.00 | 706.00 | 834.00 | 748.00 | 884.00 | 791.00 | 934.00 |

| 40 | 554.00 | 534.00 | 675.00 | 736.00 | 869.00 | 782.00 | 924.00 | 830.00 | 979.00 | 876.00 | 1030.00 |

| 42 | 611.00 | 589.00 | 744.00 | 811.00 | 958.00 | 863.00 | 1010.00 | 914.00 | 1080.00 | 966.00 | 1141.00 |

| 44 | 670.00 | 646.00 | 817.00 | 890.00 | 1051.00 | 947.00 | 1110.00 | 1000.00 | 1180.00 | 1060.00 | 1252.00 |

| 46 | 733.00 | 706.00 | 893.00 | 973.00 | 1140.00 | 1030.00 | 1222.00 | 1090.00 | 1290.00 | 1150.00 | 1360.00 |

| 50 | 865.00 | 835.00 | 1055.00 | 1155.00 | 1358.00 | 1223.00 | 1444.00 | 1296.00 | 1531.00 | 1369.00 | 1617.00 |

Technical Data

| Intensity level | Wire diameter | Min. tensile strength | Min. stress with 1% extension | Min. extension percentage when L=250 | Min. No. of 3600 twist |

| mm | Mpa | Mpa | % | ||

| General | 1.24~2.25 | 1340 | 1170 | 3.0 | 16 |

| 2.25~2.75 | 1310 | 1140 | 3.0 | 16 | |

| 2.75~3.00 | 1310 | 1140 | 3.5 | 16 | |

| 3.00~3.50 | 1290 | 1100 | 3.5 | 14 | |

| 3.50~4.25 | 1290 | 1100 | 4.0 | 12 | |

| 4.25~4.75 | 1290 | 1100 | 4.0 | 12 | |

| 4.75~5.50 | 1290 | 1100 | 4.0 | 12 | |

| High | 1.24~2.25 | 1450 | 1310 | 2.5 | 16 |

| 2.25~2.75 | 1410 | 1280 | 2.5 | 16 | |

| 2.75~3.00 | 1410 | 1280 | 3.0 | 16 | |

| 3.00~3.50 | 1410 | 1240 | 3.0 | 14 | |

| 3.50~4.25 | 1380 | 1170 | 3.0 | 12 | |

| 4.25~4.75 | 1380 | 1170 | 3.0 | 12 | |

| 4.75~5.50 | 1380 | 1170 | 3.0 | 12 | |

| Very high | 1.24~2.25 | 1620 | 1450 | 2.0 | 14 |

| 2.25~2.75 | 1590 | 1410 | 2.0 | 14 | |

| 2.75~3.00 | 1590 | 1410 | 2.5 | 12 | |

| 3.00~3.50 | 1550 | 1380 | 2.5 | 12 | |

| 3.50~4.25 | 1520 | 1340 | 2.5 | 10 | |

| 4.25~4.75 | 1520 | 1340 | 2.5 | 10 | |

| 4.75~5.50 | 1520 | 1270 | 2.5 | 10 |

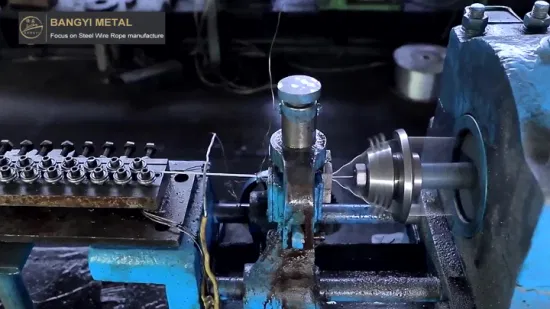

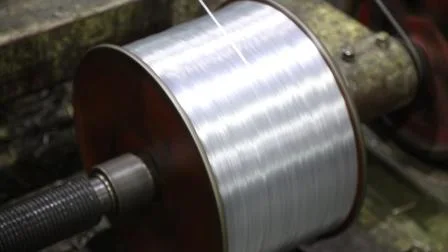

Production process

GSW producing process is phosphating, drawing, galvanizing, stranding and packing .

Package

About us

ZHEJIANG WANSHENG YUNHE STEEL CABLE CO .,LTD established in 1958,located in Hangzhou City,it is one of the leading manufacturer for galvanized steel wire and strand, Aluminium Clad Steel wire & strand for cables & communication industry in China around more than 60 years .Also it is national key supporting high-tech enterprise.The production capacity at present over 30,000 tons per year.We now have a registered capital of 200 million RMB and covering an area of 37 thousand square meters. Our company has attained ISO 9001 quality management system certifications and ISO 14001 quality environment system certifications.Our company's "Yunhe'' brand products as follows: Galvanized steel core wire and strand for aluminum conductor steel reinforced(ACSR)for power transmission lines, poles or towers,Galvanized steel wire and strand, Phosphate steel wire for optical fiber cable ,Carbon spring steel wire,Aluminium Clad Steel Wire & Strand ,Galvanized steel wire for armouring cable.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.Q: What is your terms of payment ?

A:30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: